ABS

ABS is UV-sensitive and has the potential for large fume. During the printing process, it generates an odour.

ABS is UV-sensitive and has the potential for large fume. During the printing process, it generates an odour.

Nylon has excellent mechanical qualities, including the best impact resistance for a non-flexible filament. It is extremely durable and chemically resistant.

PC(Polycarbonate) is one of the strongest materials for FDM 3D Printing and can be interesting option to ABS due to its similar qualities.

PET which stands for Polyethylene terephthalate, is a thermoplastic polymer resin of the polyester family. It is made up of two monomers and is widely utilized in practically everything, from bottles to clothing.

PLA is the easiest material to print with and has a high visual quality. It is incredibly rigid and quite powerful, but is also very brittle.

TPU is most employed in applications requiring material flexibility, although it also has a strong impact resistance. It is quite abrasion resistant and does not suffer greatly when exposed to oil and grease.

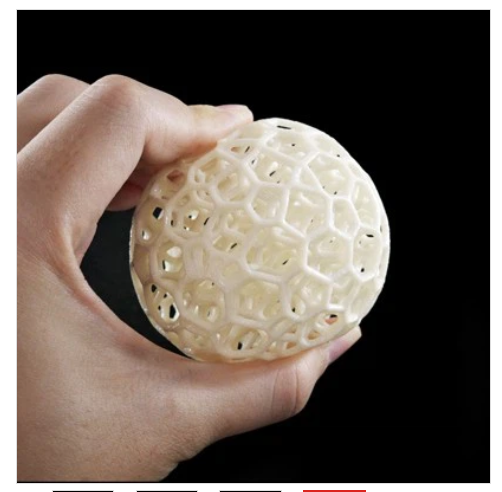

SLA (Stereolithgraphy) 3D Printing materials are typically photopolymers that are sensitiveto UV light, these materials solidify and bond to the previous layer, forming the final 3D object. These materials have a wide range of properties, including flexibility, strength, and transparency, and are often used for creating prototypes and small-batch production parts. Some SLA materials are also biocompatible and can be used for medical applications.

Standard resins generate prints with great rigidity and resolution, as well as a smooth injection molding-like finish. Standard resin is great for concept modelling, rapid prototypin, and more aesthetic 3D printing.

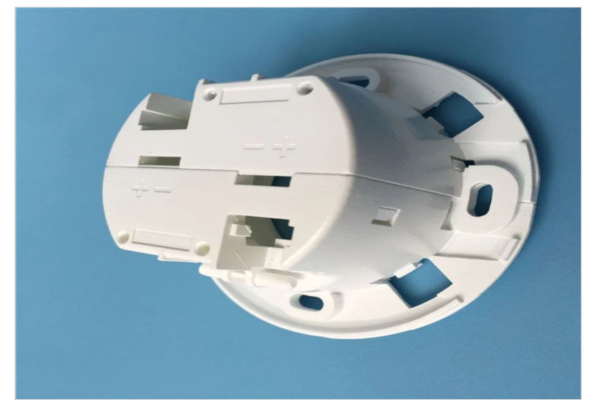

Tough resin, like ABS, was created for applications that require materials that can torelate extreme stress and strain. This material will yield strong, shatter-resistant pieces as well as useful prototypes such as enclosures with snap-fit joints or robust prototypes.

Clear resin has mechanical qualities similar to ordinary resin, but it can be post-processed to achieve near optical transparenc. Clear resin is suitable for displaying interior elementsLED housings, and fluidic devices.

Heat resistant resin is appropriate for applications requiring strong thermal stability and operations at high temperatures. It also has a high impact strength, stiffness, and temperature resistance.

Parts requiring high flexibility (high elongation at break), minimal friction, and a smooth surface finish might benefit from durable resin. Durable resin is ideal for prototyping consumer products such as snap fittings, ball joints, and low friction moving

Rubber-like resins can generate parts with low hardness and high flexibilitybut fall short of actual rubber's performance. This material is great for prototyping wearables, multi-material assembleies, handles, grips and overmolding.

Rigid resins are reinforced with glass or other ceramic particles, resulting in extremely stiff and rigid products with an extremely smooth surface finish. Molds & tools, jigs, manifolds, fixtures, electrical applications housings, and automotive parts are all good candidates.

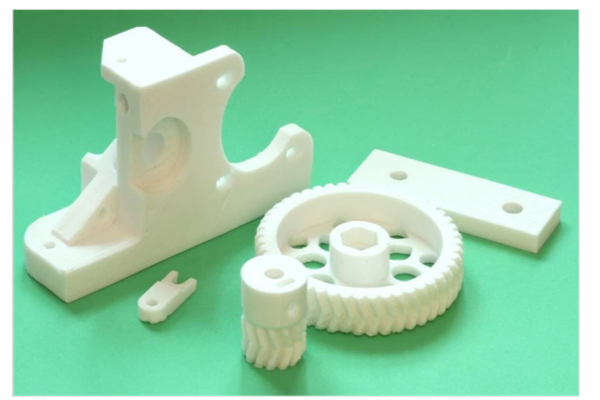

SLS materials range from impact-resitant polymers to styrene-based choices that are excellent for plaster and metal castings. SLS is commonly used for low-to-medium-volume end-use itemssuch enclosures, snap-fit parts, automotive mouldings, and thin -walled ducting. Some of our SLS technicla plastics are manufactured with flame-retardant ingredients, allowing them to meet the standards of aircraft and consumer products. Glass-filled materials, which provide better stiffness and heat resistance, are also availabl, as is fiber-reinforced plastic for maximum rigidity. SLS also gives material possibilities for rubber-like flexible parts, allowing applications such as hoses, gaskets, grip padding, and more.

Strong Polyamide 12 thermoplastics capable of replacingtypical injection moulded goods; offers food-grade, medical-grade, and flame-retardant variants.

These materials are designed with glass, aluminium, or mineral fibre fillers to provide a range of advanced features in terms of stiffness, temperature resistance, strength and surface quality.

Polyamnide 11 thermoplastics with impact resistance that provide molded-part performancein demanding situations; perfect for snap-fits and living hinges with the ability to bounce back to their original shape.

Rubber-like flexibility with good memory, tear, and abrasion resistance for prototypes and production parts.

Excellent for sacrificial patterns for prototype metal castings and low to medium production runs without the need for tooling.